Six types are available for different applications. Compact and lightweight onion digger

Onion digger (belt type with horizontal feed function, square bar type)

MODEL P040-1DHA

Horsepower required: 20 to 47.5kw-13 to 35PS

Attachable machine:Tractor, rice transplanter, etc.

Harvestable width: 1100㎜

Onion digger (belt type with horizontal feed function, blade type)

MODEL P040-1AHA

Horsepower required: 20 to 47.5kw-13 to 35PS

Attachable machine:Tractor

Harvestable width: 1100㎜

Onion digging machine (roller conveyor type with horizontal feed function, square bar type)

MODEL P040-1EHA

Horsepower required: 20 to 47.5kw-13 to 35PS

Attachable machine:Tractor

Harvestable width: 1100㎜

Onion digging machine (roller conveyor type with horizontal feed function, blade type)

MODEL P040-1BHA

Horsepower required: 20 to 47.5kw-13 to 35PS

Attachable machine:Tractor

Harvestable width: 1100㎜

Onion digging machine (without horizontal feed function, square bar type)

MODEL P040-1FHA

Horsepower required: 20 to 47.5kw-13 to 35PS

Attachable machine:Tractor

Harvestable width: 1100㎜

Onion digging machine (without horizontal feed function, blade type)

MODEL P040-1CHA

Horsepower required: 20 to 47.5kw-13 to 35PS

Attachable machine:Tractor

Harvestable width: 1100㎜

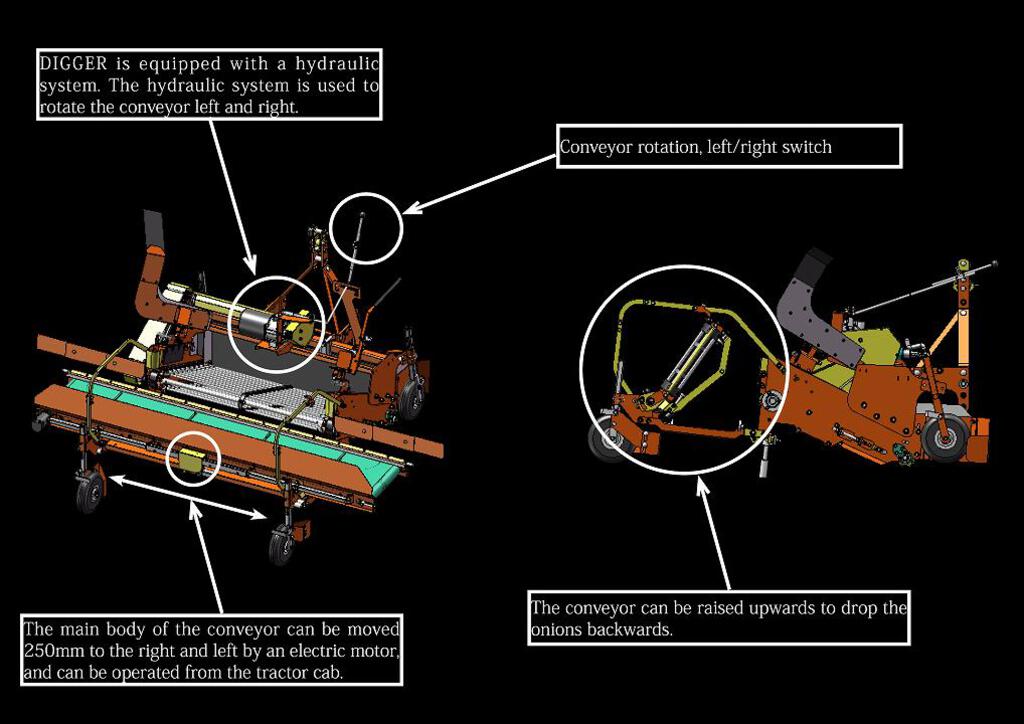

DIGGER Details

What does it mean that it is a horizontal feed function?

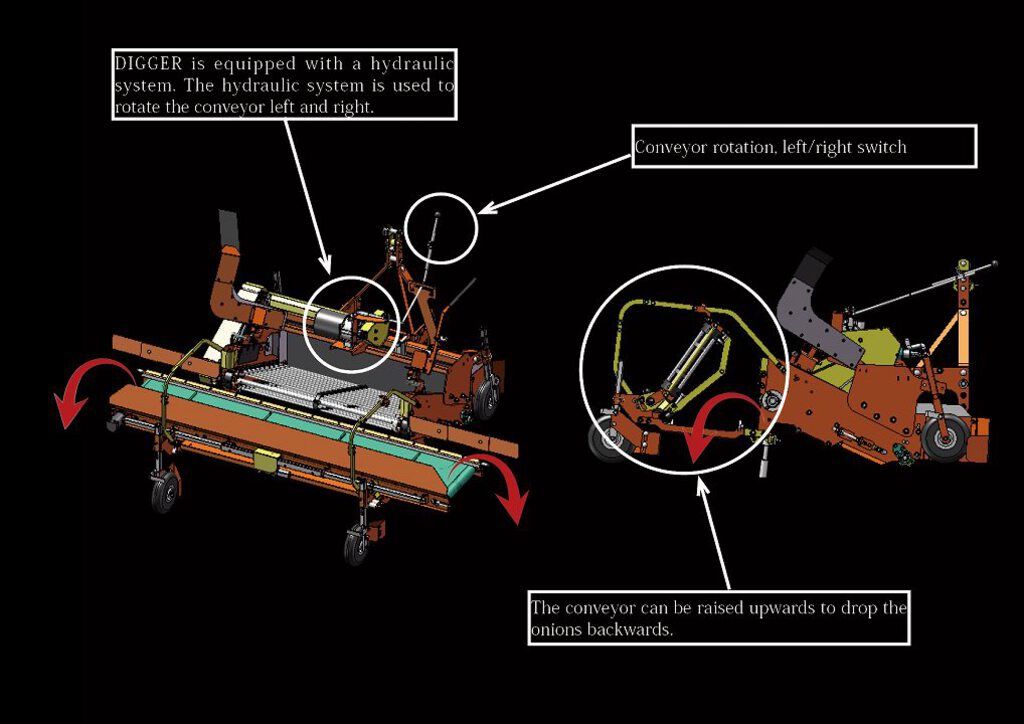

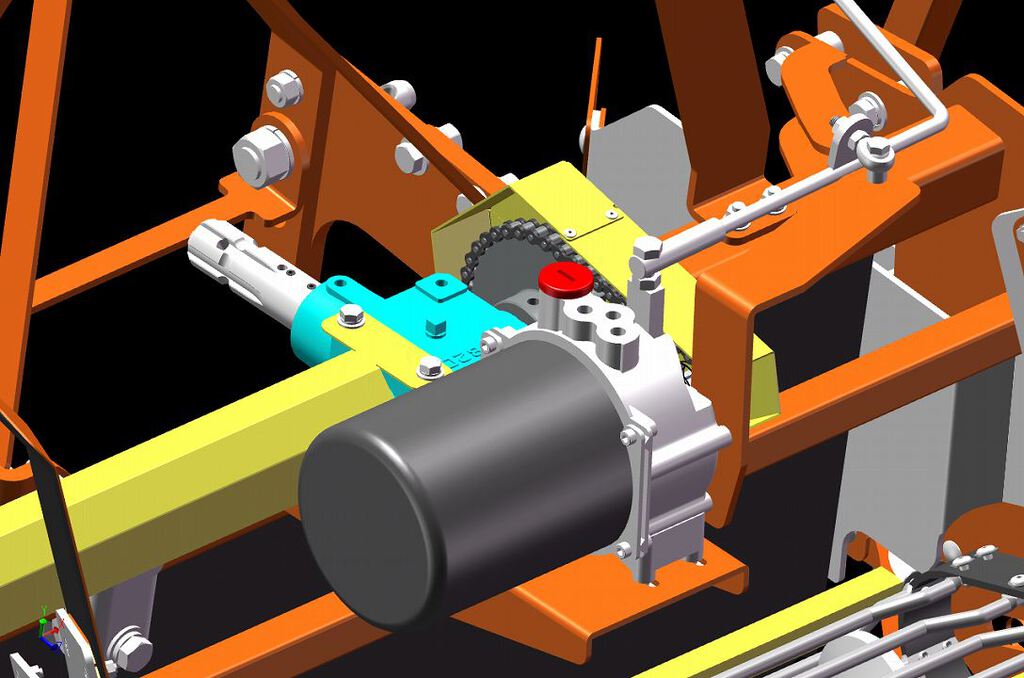

This is useful when you want to move the onions to the left or right. By moving them to the left or right, you can clear an aisle for the machine. The hydraulic motor allows you to switch left and right, so you can freely change the direction in which the onions are dropped.

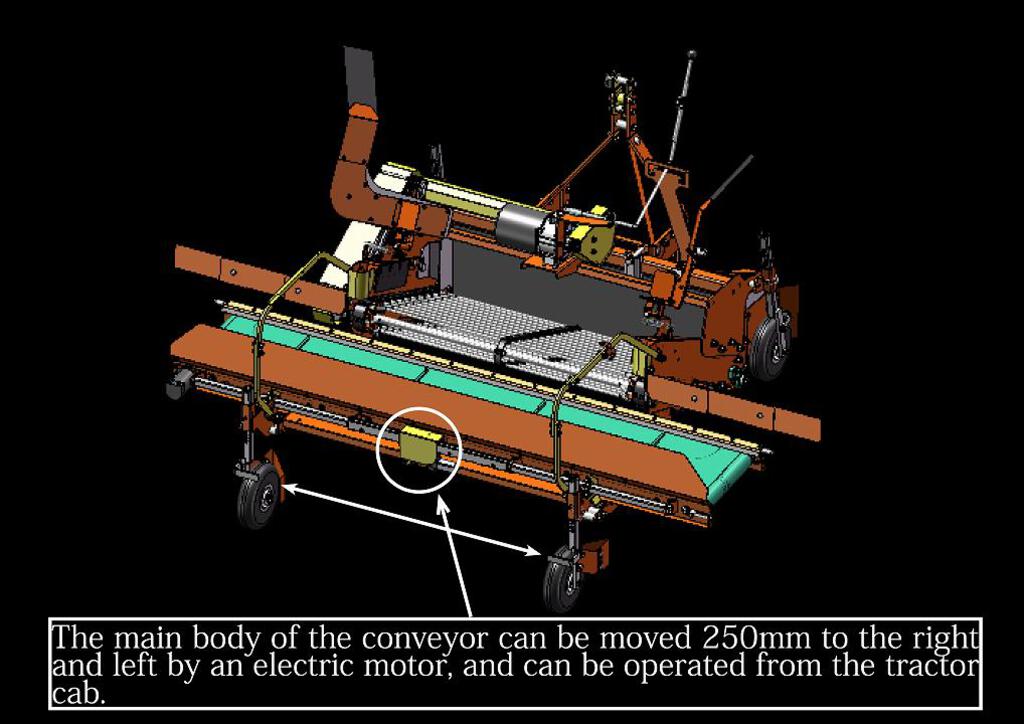

Can be slid.

The onions sent to the side can be moved to the position you want to drop them with a switch at hand. The onions can be moved 250mm to the left and right, respectively, to the position where they will be dropped. The horizontal feed is moved by an electric motor.

You can also drop it backwards.

DIGGER equipped with a conveyor can move onions in three directions. The right, left, and conveyor can be raised to move the onions backwards.

No hydraulic coupler is required.

Small, but just right.

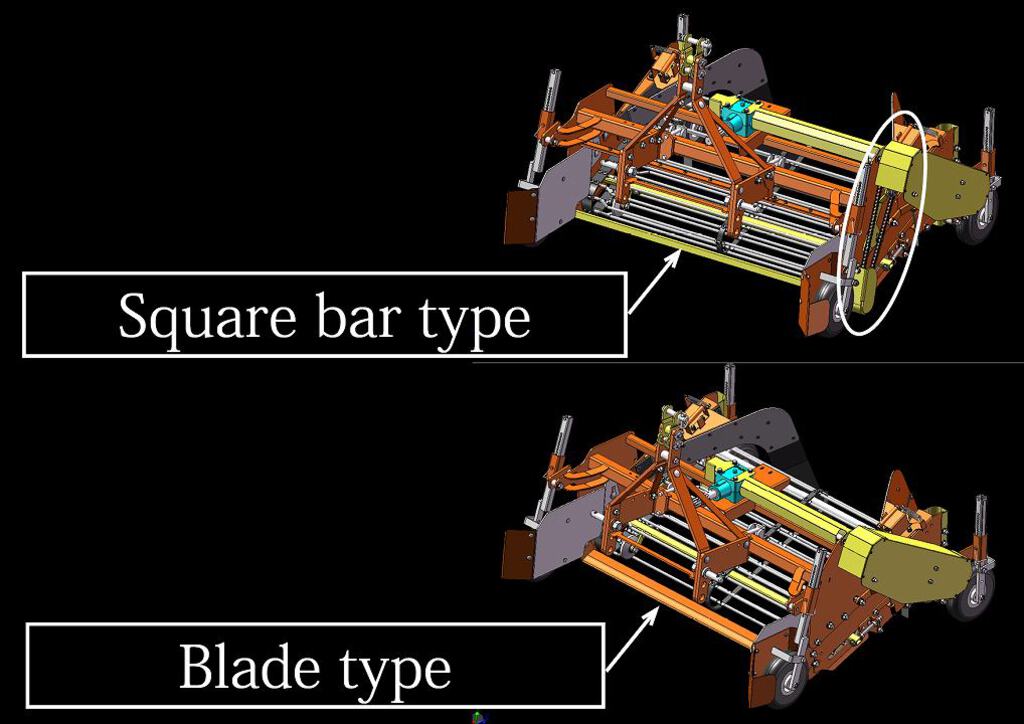

Difference between square bar type and blade type

If there are few weeds, we recommend the blade type. If there are many weeds or the soil is hard, we recommend the square bar type. The blade type can get clogged if there are too many weeds, but the square bar type keeps rotating and does not get clogged with weeds. If the soil is hard, loosening the soil with a square stick will separate the soil on the onions better.

© Basic Inc. All Rights Reserved.

Powered by ferret One